CARRYBOT: Your new warehouse co-worker

- Rapidly deployable

- Autonomous navigation technology

- Wide range of applications

CARRYBOT: Your new warehouse co-worker

- Rapidly deployable

- Autonomous navigation technology

- Wide range of applications

AI WAREHOUSE ROBOT

CARRYBOT

Due to labor shortages, overburdened shift workers, and increasingly inefficient workflows, many companies are experiencing significant losses in productivity.

CarryBot, developed by OrionStar, is an autonomous mobile robot (AMR) specifically designed for manufacturing and warehouse environments. It impresses with intelligent navigation, reliable obstacle avoidance, high load capacity, and a multi-layered safety concept. As a result, the CarryBot effectively relieves your staff, ensures flexible and secure material handling, and enables smart goods flow.

Your Key Benefits

Benefits of the CarryBot

Rapid Deployment

Thanks to integrated mapping software and individual robot mapping with intelligent information sharing to connected systems, no PC is required. Implementation time is reduced from several weeks – as is typical with traditional AGV systems – to just a few days.

Autonomous navigation technology

CarryBot features state-of-the-art navigation technology.

The integrated 240° laser-based Light Detection and Ranging (LiDAR) sensor and two upward-facing depth cameras enable precise 3D obstacle avoidance. An additional downward-facing depth camera detects even small objects on the ground quickly and accurately.

High payload requirements

With its ability to transport heavy payloads of up to max. 150 kg, the CarryBot effortlessly handles bulk goods, loose materials, heavy components, and large inventory items – eliminating the strain and safety risks associated with manual handling. Flexible carrying attachments can be adapted to a wide range of delivery requirements for various types of goods.

Multi-layered safety protection

Audiovisual signals such as the circular light indicator and warning tones help prevent collisions. In the event of collision detection, the system sends a signal to the control unit to trigger an emergency stop, effectively preventing further impacts. The integrated height restriction feature reduces safety risks caused by excessively stacked goods.

Interfaces

With approx. 500 free API interfaces, the system offers maximum integration flexibility. Based on Robot OS, the Android SDK makes development as easy as creating a mobile app.

Wide range of applications

Modular carrying attachments

Thanks to its flexibly adaptable carrying modules, the CarryBot can be precisely tailored to the requirements of different operating environments. Whether it’s loose components or packaged boxes – the robot handles every transport task with precision and reliability.

Teamplayer

When multiple CarryBots operate in the same area – for example, at an intersection – they coordinate fully autonomously, without the need for human intervention. Prioritization is intelligently managed based on each robot’s identification number, ensuring a smooth and uninterrupted workflow.

Coordinated deployment of multiple robots in micro-fulfillment centers (MFCs) significantly enhances both efficiency and flexibility. When demand spikes or transport volumes increase, the CarryBot fleet can be scaled up swiftly and effortlessly.

Master of space efficiency

With the ability to navigate tight spaces as narrow as 65 cm, the CarryBot is perfectly suited for the confined layouts of small parts storage areas.

This capability allows for optimal use of available space, boosts storage capacity, and plays a key role in enhancing overall operational efficiency.

Endurance performer

As soon as the battery level drops below 10%, the device automatically returns to the charging station.

The robot achieves an operating time of up to 12 hours on a single battery charge (tested with a 100 kg load on a smooth, hard floor). Recharging is fast – the battery is fully charged in just 4.5 hours.

Chameleon

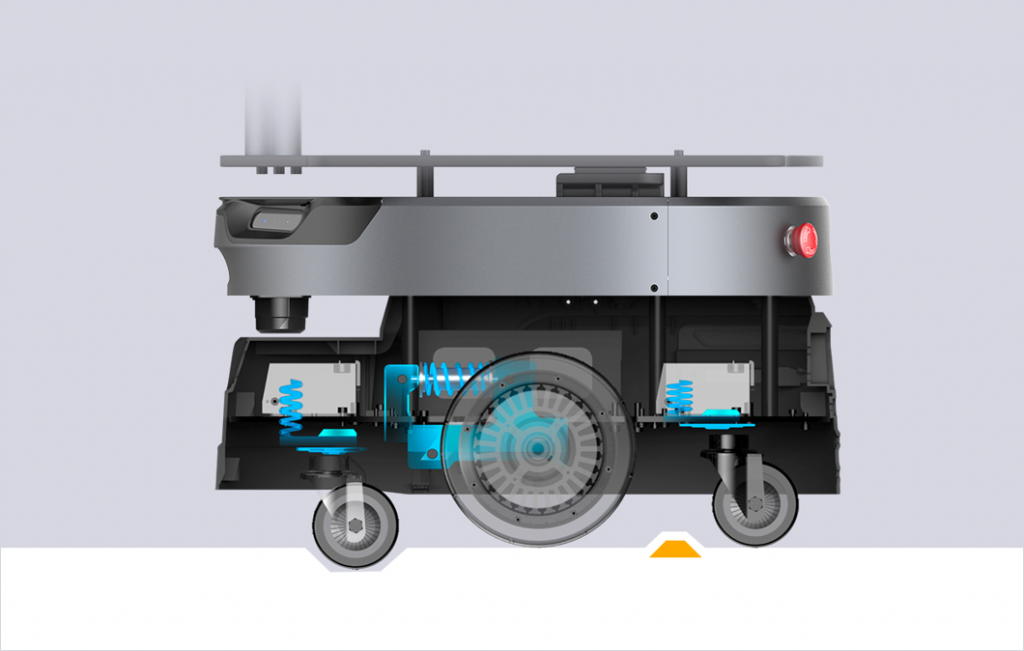

Thanks to its independent suspension system, the CarryBot easily overcomes thresholds up to 10 mm and grooves up to 30 mm deep. It adapts flexibly to different floor conditions, contributing to greater work efficiency and improved operational safety.

smart following

The CarryBot features dual intelligent follow modes – AI powered human recognition and QR code tracking – enabling safe, stable, and flexible movement in dynamic real-world environments for seamless human-robot collaboration.

Three models of the new CarryBot D150 series

Technical Specifications

CarryBot 1

CarryBot 1

|

CarryBot 2

CarryBot 2

|

CarryBot 3

CarryBot 3

|

|

|---|---|---|---|

| Overall Size | 650 mm x 525 mm x 1377 mm | 650 mm x 525 mm x 1377 mm | Robot: 650 mm x 525 mm x 1377 mm Shelf: 405 mm x 825 mm x 937 mm |

| Net Weight | 48 kg | 58 kg | 60 kg (Robot 48 kg + Shelf 12 kg) |

| Screen Size | 14-inch, 1080 FHD | 14-inch, 1080 FHD | 14-inch, 1080 FHD |

| Load capacity | Typical load: 100 kg Max. load: 150 kg |

30 kg per tray, 100 kg total (including trays) |

Typical load: 100 kg (including shelf) Max. load: 150 kg (including shelf) |

| Movement Speed | 0.3–1.0 m/s (Recommended: do not exceed 0.8 m/s) |

0.3–1.0 m/s (Recommended: do not exceed 0.8 m/s) |

0.3–1.0 m/s (Recommended: do not exceed 0.8 m/s) |

| Battery Life | Max. 12 hrs (Tested with 100 kg load on smooth, hard floor) | Max. 12 hrs (Tested with 100 kg load on smooth, hard floor) | Max. 12 hrs (Tested with 100 kg load on smooth, hard floor) |

| Charging Time | 4.5 hrs | 4.5 hrs | 4.5 hrs |

| Charging Mode | Automatic charging station, cable | Automatic charging station, cable | Automatic charging station, cable |

Value-added services

Your Managed Services Partner

As your DIN EN ISO 9001 certified digitalization partner, ICS Group offers you a seamless CarryBot solution with long-term investment protection. In addition to excellent procurement conditions, you benefit from scalable managed services for your CarryBot. From staging and configuration to onsite and after-sales services, our offerings can be tailored precisely to your individual needs.

Aktuelle Testing-Aktion

Kostenfreies access point testing

Für begrenzte Zeit (bis 31.12.2025) bietet Ihnen Cambium Networks die Möglichkeit, die Leistungsfähigkeit der Wi-Fi 6-Access Points kostenlos zu testen. Nutzen Sie dieses Angebot und verbessern Sie Ihr Konnektivitätserlebnis mit den Enterprise-Grade Wi-Fi 6 Access Points von Cambium Networks.

Kontaktieren Sie Ihren Partner ICS Group über das Kontaktformular am Seitenende und sichern Sie sich jetzt Ihren kostenlosen High-Performance Enterprise Wi-Fi Access Point. Alle Details und Teilnahmebedingungen erhalten Sie auf Anfrage.

Get your warehouse assistant now

We look forward to getting in touch with you

We’re also available by phone: +49 30 473 920 200

OrionStar is a trademark of Beijing Orion Star Technology Co., Ltd., 100041, Beijing, CN.

CarryBot Graphics, Photos and Videos on this website: © OrionStar.